Download STS Cleaning and Maintenance Guide (PDF):

English Español Français Magyar Română Українська

IMPORTANT: Regular and thorough cleaning of machine combined with other routine maintenance procedures listed in the Operator’s Manual greatly reduce the risk of fire, chance of costly downtime, and improve machine performance. Crop material and other debris can accumulate in various areas. Direction of wind, type of crop, and crop moisture content can all impact where and how much crop material and debris can accumulate. Be aware of application conditions and adjust your cleaning schedule to ensure proper machine function and to reduce the risk of fire. The areas listed in this guide may require more frequent cleaning, even multiple times per day, depending on application conditions.

Inspect and clean the following areas as needed throughout the application day:

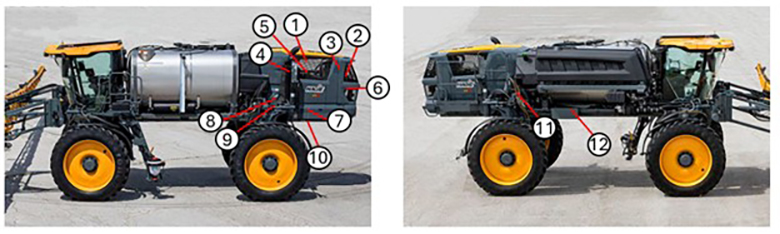

- Left and Right-Hand Hood Screens (1)

- Rear Hood Door (2)

- Fan Shroud (3)

- Top of Hydraulic Tank (4)

- Turbo(s) (5)

- Cooling Package (6)

- Frame Rail Under Hood (near exhaust) (7)

- Inside Exhaust Shielding (8)

- Aftertreatment Support (9)

- Belly Pans (10)

- Front of Power Distribution Box (11)

- Combo Oil Cooler Screen Door (if equipped) (12)

NOTE: Ensure areas around the exhaust and aftertreatment device remain debris-free. Remove the transition panel (8a) to access and thoroughly clean the exhaust area (8b). Reinstall panel after cleaning. Do not operate machine without panel installed.

READ SAFETY INFORMATION IN OPERATOR’S MANUAL

Always follow all safety procedures posted on the machine and in the Operator’s Manual. Before carrying out any inspection or cleaning, always shut OFF engine, set park brake, and remove key. Thoroughly clean machine from top to bottom with compressed air. First clean all areas accessible from platform. Start with engine compartment and work outwards and counter-clockwise to other areas around engine compartment, under the engine, and areas around the exhaust aftertreatment. Once top areas of machine are clean, proceed to cleaning areas accessible from ground level. From ground level, clean rear underside of fuel tank area. The exhaust aftertreatment area will also need to be cleaned from ground level. Once cleaning from ground level is finished, recheck engine compartment for any crop debris that could have blown in from ground level cleaning.